cvt No Further a Mystery

Manage Valve: The control valve regulates the force in the transmission fluid in the CVT. This stress is employed to adjust the pulley dimensions and, in turn, the equipment ratio.

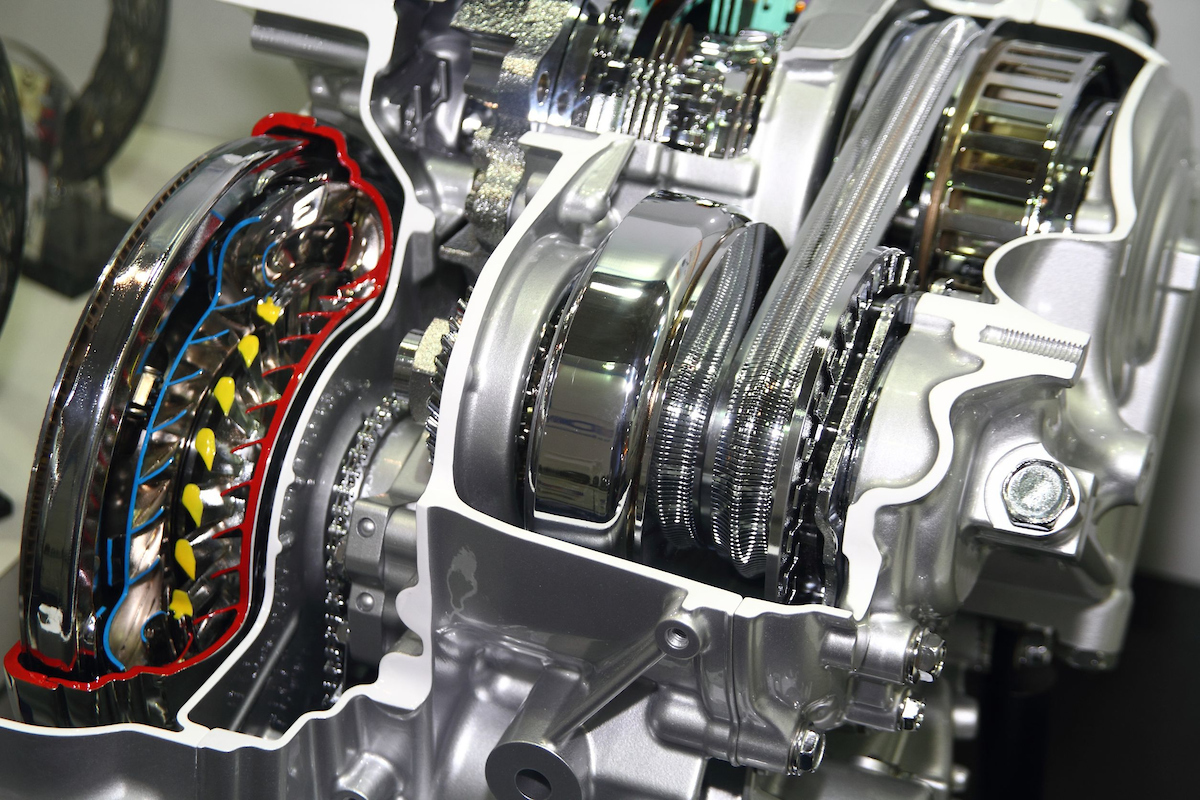

The CVT is made up of a number of factors that operate collectively to provide the continuous range of gear ratios. These parts contain:

CVT gearboxes are reasonably straightforward in their design and development and have already been in manufacturing for decades, in order that they’re reasonably trustworthy as a result. Provided that you stay with a regular provider routine, a CVT ought to be no extra problematic than a conventional automatic gearbox.

HowStuffWorks The variable-diameter pulleys are the heart of the CVT. Each pulley is crafted from two 20-diploma cones struggling with each other. A belt rides in the groove in between The 2 cones.

In the hydrostatic CVT, the productive "equipment ratio" is varied by varying powerful displacement of your pump, which can fluctuate the amount of oil sent to the motor(s) in a specified motor velocity (RPM). There are numerous ways in which this may be accomplished, a single getting to divert several of the pump's output back again on the reservoir by way of an adjustable valve.

By next the proposed servicing schedules, utilizing the correct transmission fluid, and steering clear of extreme masses or higher-temperature Procedure, you may help lengthen the lifespan within your CVT transmission.

CVTs don’t use gears, but knowledge them is still less complicated if you will get how equipment ratios function. So, Allow’s start there.

The generate ratio could be set to infinity (i.e. a stationary output disk) by shifting the output disk to the center of the enter disk. The output course may also be reversed by moving the output disk earlier the center of your enter disk. The transmission on early Plymouth locomotives worked this fashion, whilst on tractors applying friction disks, the choice of reverse speeds was generally restricted.[29]

Acceleration was constrained and smoothed in the utilization of force accumulator and aid valves Positioned between the pump and motor, to forestall the unexpected improvements in speed possible with direct hydraulic coupling. Subsequent variations bundled preset swash plate motors and ball pumps.[citation wanted]

CVT in the Claas Mercator Incorporate harvester. The pulley's effective diameter is modified by pushing The 2 conical discs either towards or far from each other.

Even though CVTs provide various Positive aspects, they are not without the need of their troubles. Here are some typical challenges linked to CVTs:

This is often an enlightening and nicely dapatkan produk composed short article. How can the pulleys alter diameters? or could it be the belt slips in excess of to diverse diameter pulleys While using the varying speeds.

In the hydrostatic CVT, the helpful "gear ratio" among the motor as well as driving wheel(s) is the result of a difference between the pump's displacement—expressed as cubic inches or cubic centimeters for each revolution—plus the motor's displacement.

As the space amongst the pulleys plus the length from the belt isn't going to alter, each pulleys must be modified (1 bigger, the other smaller) at the same time to maintain the correct volume of rigidity over the belt. Simple CVTs combining a centrifugal drive pulley with a spring-loaded driven pulley often use belt rigidity to result the conforming changes inside the driven pulley.